Medical industry

Even the sector of medical technology is not exempted from innovations in machinery, tools and treatment techniques and is subject to constant adaptation and regulatory tightenings. In this respect, the performance characteristics of the components demanded by doctors, such as reduced weight, lower wear rates, high chemical resistance to body fluids and cleaning solutions, must not be neglected. Stricter specifications also apply to the source materials manufactured as semi-finished products.

GEHR is currently expanding its portfolio in accordance with the requirements of DIN EN ISO 13485 in order to comply with the required product safety. It goes without saying that the individual process steps are carefully documented and the products are traceable. In addition to the necessary approval of the semi-finished product according to ISO 10993, the use of biocompatible raw materials can be traced. Possibly required sterilisation procedures of the subsequently processed components can be considered as well as a possible radiation resistance.

Properties

Approvals for raw material / semi-finished product / processes

We have introduced a quality management system for our production in accordance with the process-oriented standard ISO 13485, which takes into account specific requirements for medical products, such as product safety, detailed documentation and proof of compliance, as well as the establishment of a risk management system.

Chemical resistance

Products in the medical industry can be acidic, alkaline or neutral. Materials used here must be able to withstand these contacts. Chemicals are also used for cleaning the production systems. Therefore, the machine components must also meet the requirements.

Thermal resistance - including hot water resistance

Processing machines in the medical industry can be exposed to very low temperatures (in the cooling process) and to very high temperatures (in the cooking phase), which the components must withstand for a long time. Therefore, the appropriate suitability of the material is absolutely indispensable.

Mechanical strength

Polymer materials are often used as substitutes for other materials. Therefore, there are also increased demands on the strength here.

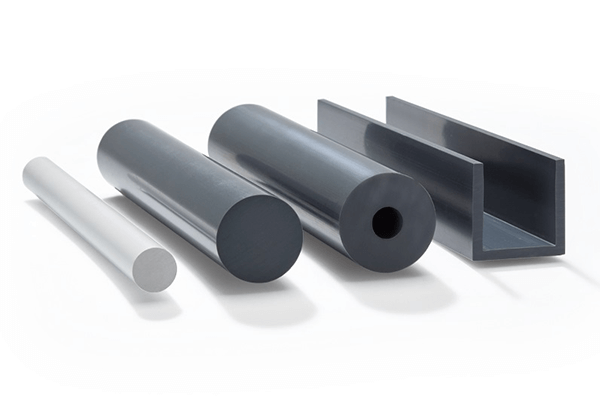

Construction material

Based on the wide variety of property profiles of plastics, the industrial sectors are gaining increasing importance. The variety and combination possibilities of different polymers open up a wide range of possible applications as construction material. Regardless of the type of connection, the thermal requirements, the chemical resistance or the necessary approval of the individual application, the extensive range of polymer materials offers a solution for almost every problem.

Radiation resistance

Depending on the respective application, polymer materials can come into contact with a wide variety of radiation types. These can range from daylight to infrared and ultraviolet rays or exposure to radioactive radiation and are referred to as electromagnetic radiation. The material resistance can vary from wavelength to wavelength. The shorter the wavelength range that comes into contact with the component, the greater the risk of damage to the plastic. Therefore, appropriate knowledge is indispensable for choosing the right material for example for components used in the aerospace industry or in medical technology applications, such as radiation therapy or the sterilisation of components, since radiation impairs elasticity and toughness.

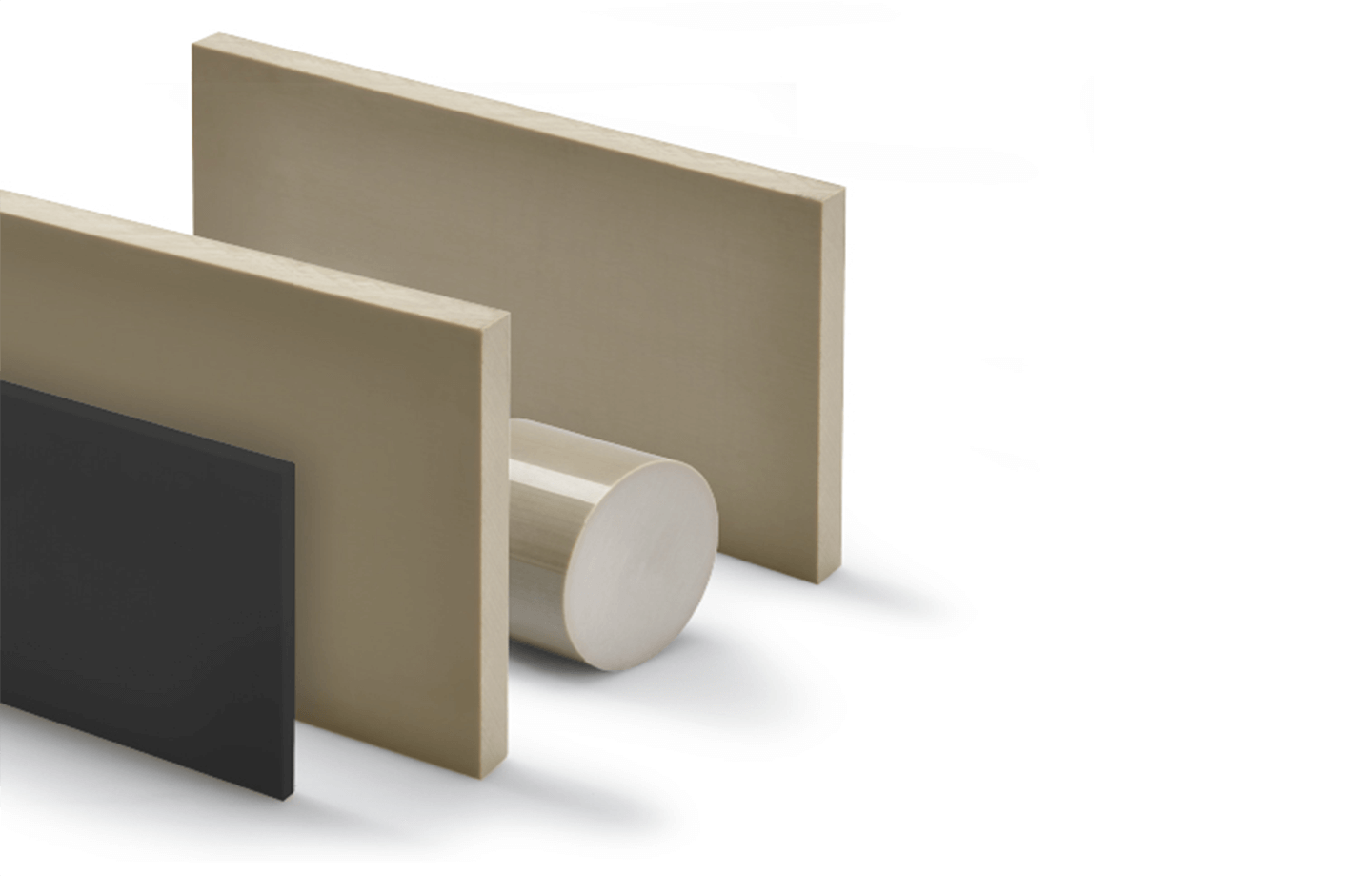

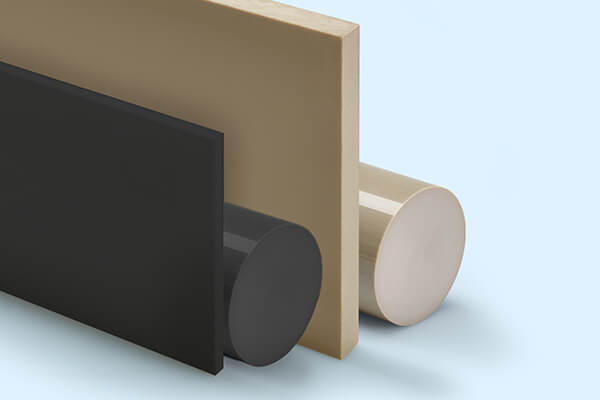

Our products for the Medical industry

MEDI-GEHR PEEK MG

MEDI-GEHR PPSU MG

MEDI-GEHR PP-HT MG

MEDI-FIL-A-GEHR PEEK MG

You can reach us

Tel: +1 610 497 – 8941

Fax: +1 610 497 – 8901

GEHR Plastics Inc.

24 Creek Circle

Boothwyn, PA 19061

USA

You’re interested in our materials or you have a question about a particular product?

Please send us an e-mail:

or use our contact form.

We will get in touch with you as soon as possible.

GEHR Facilities

Our facilities and sales offices you find

here.